Complementos de procesamiento de minerales

Optimización de su operación de procesamiento de minerales

Nalco Water es un líder mundial en reactivos y soluciones para el procesamiento de minerales. Contamos con décadas de experiencia en una variedad de mercados y más de 1,600 asociados dedicados a la investigación, el desarrollo y la ingeniería en todo el mundo. Nuestro alcance global y especialización nos ayudan a ofrecer soluciones de procesamiento de minerales técnicas, económicas y ambientalmente sostenibles desde la mina hasta la fábrica.

Nuestra cartera diversa de complementos de procesamiento de minerales abarca una variedad de aplicaciones e incluye modificadores reológicos, complementos de filtración, modificadores de crecimiento de cristales, estabilizadores de líquidos, estabilizadores de oxalato y reactivos para la remoción del ácido húmico. Al lograr la optimización del proceso de minería, Nalco Water puede ayudarle a maximizar la productividad, mejorar el rendimiento y lograr un impacto positivo en sus ganancias.

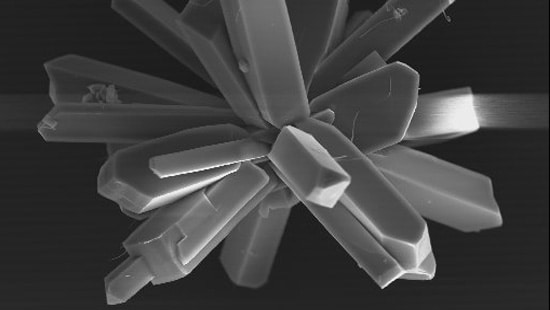

Destacado: modificadores de crecimiento de cristales

En el entorno competitivo del refinamiento de la alúmina, las plantas de procesamiento enfrentan el desafío continuo de aumentar el rendimiento y al mismo tiempo mantener el tamaño y la calidad del cristal de hidrato. Nalco Water ofrece programas de modificadores de crecimiento de cristales especialmente diseñados para usar dentro de los circuitos de precipitación del proceso Bayer. Los programas ofrecen un mayor control de los mecanismos de aglomeración y formación de núcleo, lo que puede tener un impacto positivo en el control del tamaño del producto final, el rendimiento del líquido, la clasificación del hidrato y el control de interferencia del oxalato.

Los CGM son solo uno de los productos de la cartera integral de complementos de procesamiento de minerales de Nalco Water. Contáctenos para hablar sobre sus necesidades operativas específicas y obtenga más información sobre nuestras soluciones de procesamiento de materiales.

Flotation 360™

La optimización del procesamiento de minerales puede parecer un objetivo en movimiento. Un cambio en el mineral, una formulación incorrecta o la falta de equilibrio entre la recuperación y la calidad pueden afectar sus resultados. Pero Nalco Water tiene la solución para usted: Flotation 360. Esta tecnología digital ayuda a maximizar la productividad y a optimizar el rendimiento de su circuito de flotación.

Optimice su circuito con las capacidades predictivas de Flotation 360 para ayudar a:

- Mejore el rendimiento para optimizar la recuperación y la rentabilidad

- Mejore la visibilidad de los impactos potenciales de futuros cambios en el mineral, lo que permite mitigar cualquier desafío por adelantado

- Optimice la dosificación de reactivos y el consumo de productos químicos, mejorando el coste total de las operaciones

- Reduzca los desafíos de mantenimiento, como fallas en la válvula de la celda de flotación, y dedique menos tiempo a la resolución manual de problemas

Historias de éxito sobre complementos de procesamiento de minerales

El programa de modificadores de crecimiento de cristales mejora la eficiencia/rendimiento, la sustentabilidad, el rendimiento y los costos en una planta de alúmina

En una planta de alúmina en el Mediterráneo, la responsabilidad social corporativa tuvo un papel fundamental en sus operaciones diarias. Con foco en la seguridad, el uso óptimo de recursos y los costos reducidos, la planta buscó métodos nuevos y efectivos para mejorar la eficiencia general del proceso. En asociación con la planta, Nalco Water determinó que la aplicación de un modificador de crecimiento de cristales podría ayudar a conseguir los resultados que la planta necesitaba.

Descarga el estudio de caso para saber cómo el programa de modificadores de crecimiento de cristales de Nalco Water ayudó a generar un valor de más de €743,000 al año en mayor rentabilidad y ahorro.

Impulsamos la innovación en el procesamiento global de minerales

Nalco Water pone gran énfasis en la investigación, el desarrollo y la innovación. En nuestro compromiso de abordar los desafíos del procesamiento de minerales, hemos reunido equipos dedicados de químicos e ingenieros para manejar nuestros centros de investigación técnica centrados en los clientes en todo el mundo. Desde los Estados Unidos hasta Australia Occidental, los Países Bajos e India Occidental y cualquier otro lugar en el mundo, Nalco Water ofrece un equipo de especialistas conectados en todo el mundo que son locales para su planta y están muy al tanto de los desafíos de la región que podrían tener un impacto en sus operaciones.

Complementos de procesamiento de minerales de Nalco Water

Este dispersante es una formulación acuosa de bajo peso molecular especialmente diseñada para ser un dispersante y anti-incrustante eficaz en aplicaciones de procesamiento de minerales donde se operan circuitos con alto contenido de cal. El dispersante funciona mediante la reducción de la viscosidad de los lodos minerales. También puede modificar la formación de cristales y, por lo tanto, alterar la naturaleza y la tasa de deposición de incrustaciones.

- Mejora la reología de la lechada.

- Limpia las superficies minerales y mejora la recuperación de minerales valiosos.

- Reduce la tasa de deposición de incrustaciones donde prevalecen los problemas de incrustaciones.

- Evita la capa de limo en minerales valiosos.

- Propiedades no espumantes.

- Estable a altas temperaturas.

| Productos |

|---|

| NALFLOTE 600-05 |

Los complementos de extracción de agua Filtermax se utilizan principalmente para ayudar en la filtración de concentrados minerales para reducir la humedad de la torta de filtración y mejorar las características para manejar la torta de filtración. Funcionan reduciendo la tensión superficial del agua y, lo que es más importante, haciendo que las superficies de las partículas minerales sean más hidrófobas (repelentes al agua), lo que permite una mayor reducción de la humedad.

- Menor humedad de la torta, lo que reduce los costos de secado y flete.

- Tasas de filtración más rápidas, lo que reduce la inversión de capital en filtros.

- Mejor liberación de la torta, lo que aumenta la eficacia de los filtros.

- Reduce el cegamiento del tejido filtrante, lo que mejora la vida útil de la tela.

| Productos |

|---|

| FILTERMAX 470LV |

| FILTERMAX 440GFM |

Programas, productos, equipos y servicios

Vea nuestros productos de complementos de procesamiento de minerales

No pudimos encontrar resultados para "".